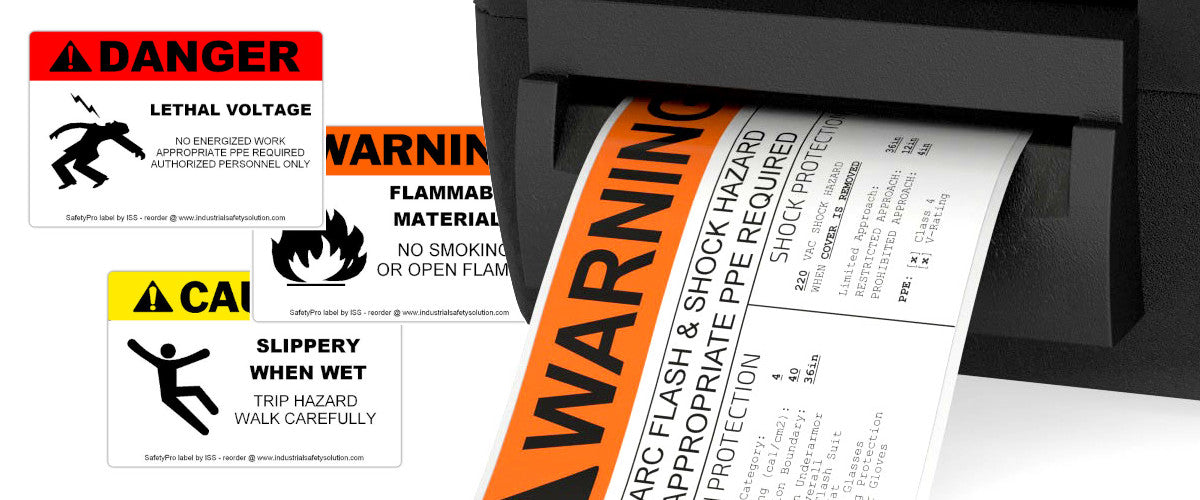

Increasing safety in your workplace through effective labeling is simple, when you know what is needed. SafetyPro equipment and supplies can help you create labels and signs that will warn of hazards, with most labels accessible in minutes.

Parts of a Safety Label

There are several standard components of a safety label. Each is important, and all of the parts combined make a label effective.

Label Size

One of the very first things you'll decide about a safety label is the completed label size. Some safety labels have very specific size requirements, such as pipe labels. Other labels are sized according to the application. A good rule of thumb when considering the correct size for your safety label is this question: Can my safety label be easily read at a common working distance for this hazard?

Many safety labels are created using either 2" vinyl labeling stock, or 4" vinyl labeling stock. These two sizes cover the most common working distances; 2" is generally used for smaller equipment where the worker will be in very close contact, and 4" is used for larger equipment. 4" may sometimes be used to alert a worker of more significant risks.

Label Style

Some applications require specific label styles, such as ANSI compliant or OSHA compliant labels. Regulatory compliance is the responsibility of each site manager, and SafetyPro can help with ANSI and OSHA compliant supplies.

Label Color(s)

Many general safety labels can be created using single-color thermal resin ink on a single-color vinyl label stock. These are known as monochromatic labels, and they are the most widely found labels. Pipe labels are also, in general, monochromatic (though, Ammonia labels are generally composite labels made of several monochromatic labels in specific sequences).

Monochromatic labels can be created in a variety of color combinations. Some common examples include:

- Black on white vinyl labels

- White on black vinyl labels

- Black on orange vinyl labels

- Black on yellow vinyl labels

- White on red vinyl labels

- White on blue vinyl labels

- White on green vinyl labels

- And many more

Some applications require multi-color labels. These include some ANSI labels, as well as arc flash labels, RTK, and GHS labels. SafetyPro offers a complete lineup of multi-color label stocks for these applications.

Label Headers

Most safety labels will have a header, which designates the hazard level. The most common english headers are: Warning, Danger, Caution, and Notice. These headers are placed at the top of the label, and may be in color on certain labels (usually when the label is white vinyl with a color stripe). Some SafetyPro label stocks include a pre-printed header in either white or black.

It is important that your label header match your hazard level, and that your header color match your site-specific requirements. SafetyPro offers the widest variety of color header stocks in the industry, to match any requirement.

Label Icons / Graphics / Pictograms

The most effective safety labels will convey the general hazard information using only color and images. These images are usually called icons, graphics, or pictograms. The color conveys the level of hazard, but the image conveys the specific type of hazard.

The SafetyPro comes with software which includes a variety of safety images. You may create labels with a single image, or multiple images, as needed. When necessary, you may combine multiple labels, to create the exact identification profile necessary for your risk.

Label Text

The text on a safety label should be short, bold, and easily readable. Avoid long descriptions or legal disclaimers when possible, and focus on specific risks and mitigation information. Arc flash labels have very specific requirements for label text, as do some ANSI or OSHA labels. Make sure to be aware of any legal or regulatory requirements when creating your safety label.