Arc Flash Labeling is Critical

One of the greatest electrical hazards in any facility is the risk of arc flash. If your facility hosts high-voltage cables or equipment, there is a potential for arc flash events. You can mitigate these risks through design choices, inspections, and a solid hazard communication plan that includes arc flash labeling.

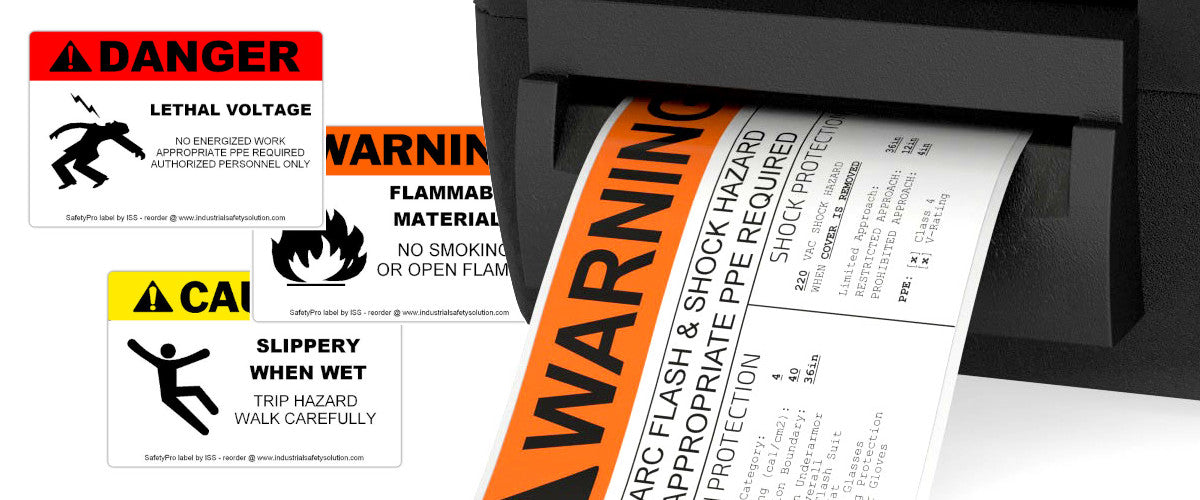

Industrial Safety Solutions has been in the arc flash labeling business for decades, helping to warn personnel of arc flash risks through effective safety labeling. Arc flash labels produced with SafetyPro equipment and supplies quickly instruct the viewer on the hazards they may encounter when working with a particular piece of equipment, and how to properly protect against those hazards with PPE.

The major components of an arc flash label are usually included in template form, and are often generated automatically from a software package such as FacilityWare, SKM, Etap, or Easypower. Even so, it is important to understand the elements of a valid NEC NFPA 70E arc flash label. The following is for informational purposes, and cannot substitute for an arc flash study performed by a qualified engineer.

Parts of an Arc Flash Label

- Hazard Category: The NFPA 70E has four different hazard categories. These categories dictate the types of clothing and other PPE that must be worn to help mitigate arc flash risk. Your arc flash label should list the hazard category as a number between 1 and 4, so that viewers can very quickly determine if their PPE is adequate.

- Minimum Arc Flash Rating: This is a measurement in calories/cm2 or Joules/cm2 of thermal energy at a working distance from an arc fault. Some sites may choose to use specific color headers, to help personnel quickly identify ratings. SafetyPro offers a variety of color headers to help with this need.

- Flash Protection Boundary: This is the shortest distance at which a worker may receive permanent injury in an arc flash event. Permanent injury may be as simple as second degree burns, but is often much worse. This rating is for workers who are not protected by flame-resistant clothing; proper PPE can mitigate this risk.

- Header: The color stripe, attention triangle image, and wording at the top of the arc flash label are called the header. It is up to the facility to determine which color and wording is appropriate for a given risk. In general, warning level labels are orange, and danger level labels are red. However, these colors may vary based on site-specific goals.

- Sub-Header: This optional but recommended portion of an arc flash label helps the viewer quickly identify the risks that the label is attempting to communicate, and the actions that must be taken. Templates with or without a sub-header are available in most software packages.

- Required PPE: Arc flash labels will often list specific PPE that is required, in addition to a hazard category which describes PPE in general terms. Listing specific PPE may be helpful to inform personnel who may not be familiar with the hazard category ratings and what they mean.

Though arc flash represents a significant hazard in the workplace, mitigation is possible. PPE is vital, but an effective labeling strategy is your next best line of defense. After all, if workers aren't sure what the risks are, they won't be able to determine what actions they need to take.

SafetyPro can help you mitigate arc flash risks through effective arc flash labeling. We offer the most comprehensive selection of arc flash labels in the industry, made from durable vinyl that is designed to last. Join the thousands of facilities that trust SafetyPro to help them keep their workers safe.