One of the most important features of a label created using SafetyPro printers and supplies is extreme durability. Labels that you print with SafetyPro are chemical, scratch, and UV resistant. The secret to their durability lies in the printing process itself.

SafetyPro labels are created using a thermal transfer process involving perfectly formulated full-resin inks, and chemically matched vinyl or poly labeling materials. The thermal transfer printing process involves multiple steps and parts.

The Parts of Thermal Transfer Printing

- Ribbon / Ink: SafetyPro ribbon inks consist of thin-film plastic backing coated with full-resin inks. Our ribbon inks are coated "Coating Side Out" (CSO), which means that the ink is on the outside of the wound roll.

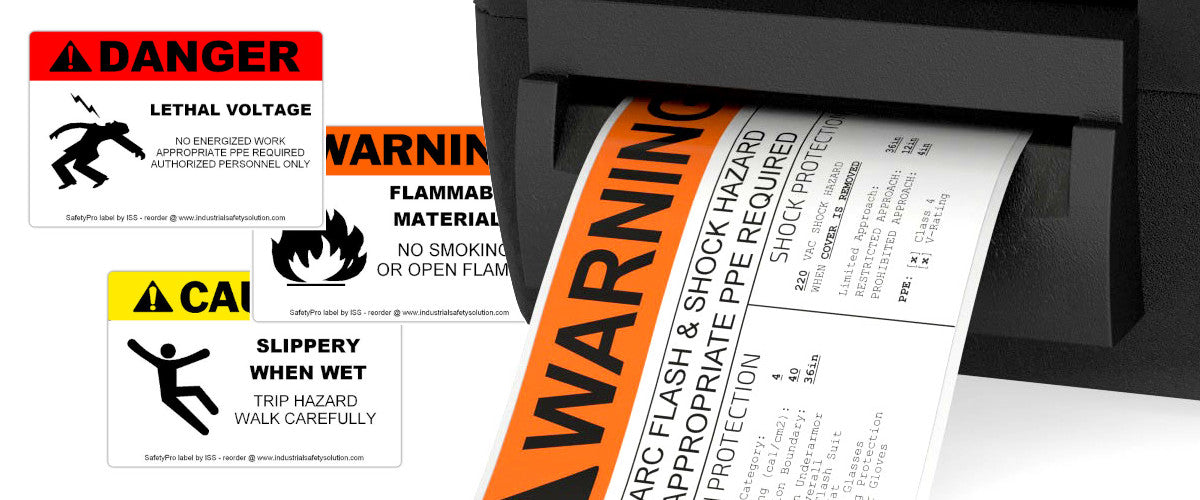

- Labeling Tape: We offer vinyl and poly labeling tapes, including our Premium Vinyl Labeling Tape and our Die-Cut Arc Flash labels. This is the material that the ink will be embedded into.

- Print Head: SafetyPro printers are equipped with a high-temperature, high DPI thermal print head, which is aligned perfectly within the printer and positioned behind the ribbon when the printer is loaded.

- Platen: Sometimes described as a rubber roller, the platen ensures that the materials are firmly seated against the print head at print time.

The Process of Thermal Transfer Printing

To produce a perfect thermal transfer, your printer and supplies must work together throughout the print process. The ribbon, label tape, and print head must be matched to ensure a complete transfer. The process works like this:

- Ensure that your SafetyPro is loaded with compatible supplies, including full-resin SafetyPro ribbon, and vinyl or poly labeling tape.

- Supplies will be loaded so as to be between the Print Head and the Platen. At the top / center of the platen is where the printing starts.

- At print time, the high-resolution print head will be super-heated at the pixel level, as the materials are moved through.

- The heated resin is melted into the surface of the vinyl, and the high-temperature ribbon backing is left with a clear "window" where the printed resin ink is transferred.

- Both the completed label and the used ribbon are fed out the front of the SafetyPro printer for cutting and immediate use.

If your application requires a durable label that may be applied indoor or outdoor, SafetyPro thermal transfer labels made with full-resin ink and vinyl or poly labeling tape are the solution of choice. SafetyPro offers a wide variety of equipment and supplies to match any application.

Browse our selection today, and get your labeling project started right!